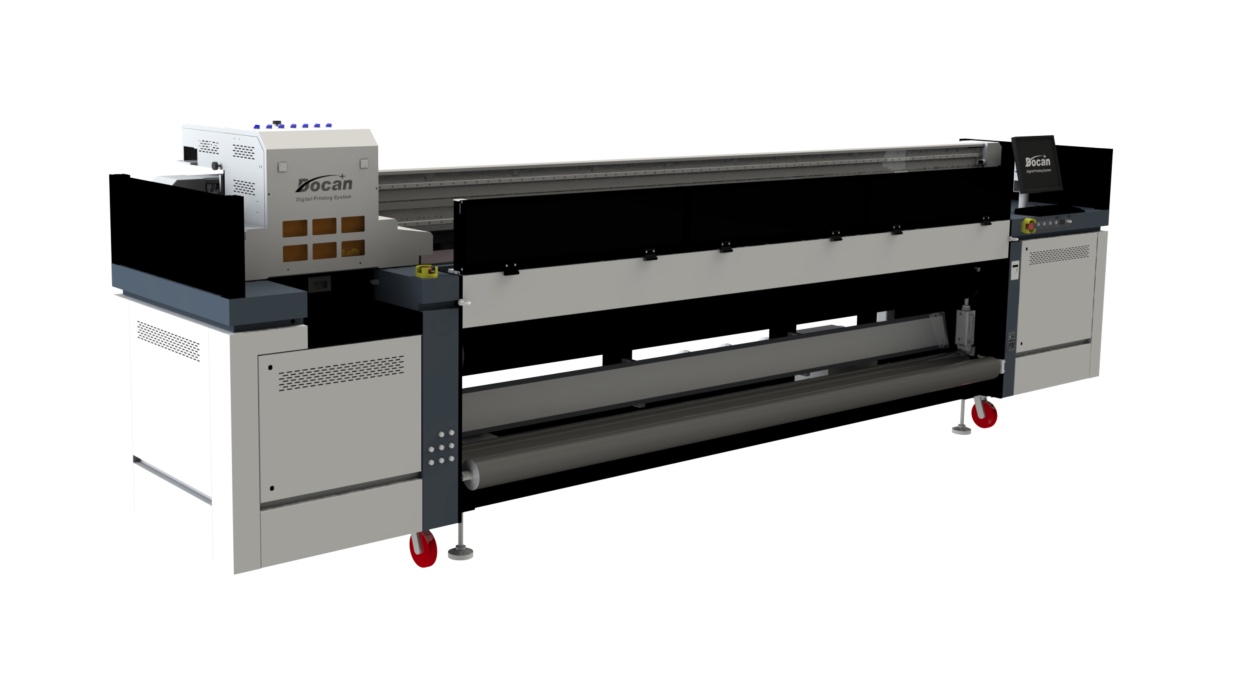

DOCAN UV Roll-to-Roll Printer S3200

The S3200 is designed to produce high quality and precise prints. Users can obtain very clear and high saturation prints in outdoor advertising, especially in lightbox fabric, backlit and ceiling printings. It handles the best quality printings on 320cm wide flexible materials and can print narrower medias accurately as well.

Using the UV ink it can produce excellent images on various materials like banners, vinyl, mesh, one-way vision, foil, backlit fabric, etc. The ink is environment friendly. Also, it offers various ways of printing the white when printing material is in color and allows to print the three-layer spot colors which means printing color-white-color at one time. |

|

| The printhead options are Konica Minolta 1024i 6-13pL, Ricoh Gen5 7pL and Kyocera KJ4A 3,5pL . The printing colors are Lc Lm Y M C K , White and Varnish are optionals! |

DOCAN UV Roll-to-Roll Printer S3200

VARIABLE COLOR ALTERNATIVES

| COLOR CONFIGURATIONS | ADVANTAGES |

| |

4 color inks print on colored or white substrates perfectly. |

| |

Transparent and colored substrates are printed directly and at high quality. Highly bright and vibrant colors are displayed thanks to the white layer printed as the last layer under the image. |

| |

4 color inks print on colored and transparent medias with white and varnished applications in vibrant, eye-catching and bright tones and last longer. |

| |

Including Light Cyan and Light Magenta 6 color inks print excellent light tones and sleek gradations. |

| |

7 color inks including White color print vivid jobs with high precision clear edges in various ways. |

| |

The white and varnish can be printed with Lc, Lm, YMCK inks simultaneously to expose flashy and attractive images for distinctive applications by printing the varnish layer. |

WHITE INK PRINT VARIANTS

| IMPLEMENTATIONS | OVER-PRINTING | UNDER-PRINTING |

| White ink at the area of image | |

|

| White ink at the area of job | |

|

| Colors and white ink individually | |

|

| White ink and colors individually | |

|

PRINT HEADS

High resolution and high-quality piezo electric printheads can achieve excellent production performance and vivid bright colors with variable dots technology.

INK CURING SYSTEM

Ink curing system operates with water-cooled LED UV lamps with 3 power levels which has long life time, more silent operation and more suitable for printings on sensitive materials like Polycarbonate, Light Box fabric, etc. or printings with varnish application. Excluding the use of VOC (Volatile Organic Compounds) the UV curable ink is environmental friendly and has no bad smell. Dreawer-type UV lamp cassette makes easy to replace the UV lamp when needed. |

|

MEDIA TRANSFER SYSTEM

|

|

Dual roller for easy loading and transmissioning the media smootly. The positioning ring keeps madia properly. The maximum material width is 320cm.

|

|

|

|

WINDING ROLLER

Industrial take up & feeding system with 2 front, 2 rear durable and long lasting rubber rolls to open and wrap material before and after printing. Equiped with potentiometer to adjust the tension level of the releasing and winding rollers during material changes. The rollers are able to forward and reverse thanks to speed and rotation direction controller. Air compressor connection is required to operate the system.

|

|

GUIDE RAIL

Equipped with Japanese THK silent double guide rail with X axial plastic raster and Italian Megadyne belt which ensures straight carriage moving to achieve accurate printing.

PRINTHEAD TRANSPORT SYSTEM

Thanks to the high-precision impact sensors on both sides of the head transport mechanism, the print heads are not damaged from curled, swollen or surged materials. The mechanism has anti-static devices to prevent electrostatic effect that disrupts the image quality. |

|

INK SUPPLY UNIT

Automatic high-volume Ink Supply system ensures continuous printing. The white ink has automatic stirring and circulation system, which avoids the clog of the white printhead. The system continuously circulates the ink between the print head and white ink tank. The ink negative pressure system control panels on the head transport mechanism for white and colors to ensure continuous and stable negative pressure. Each sub in tank have independent heating devices for easy adjust and control the temperature. The ink sensors warn user when the level gets low. |

|

DIRECT PRINTING

Can print on up to 1-2mm thick flexible medias. The maximum roll media weight is 100kg. Equiped with LED light box to observe the print quality and status.

ONYX RIP SOFTWARE

ONYX RIP Center software provides the control and simplicity needed to get started in wide format print production and achive consistent high-quality output. The versatile tools in ONYX RIP Center software make it easy to prepare jobs and produce sellable prints faster.

With advanced RIP technology, the user can get smooth gradients, vivid images and sharp small size text. The ICC color management workflow provides vibrant and bright colors. |

SPECIFICATION

| General Information | ||||||

| Model | DOCAN S3200 | |||||

| Category | UV Roll-to-Roll Printer | |||||

| Printing Size | 320cm. | |||||

| Printing | ||||||

| Printing Technology | Drop-on-demand piezo electric inkjet. Variable Drop Technology with minimum drop size of 3,5pL | |||||

| Printing Heads | KM-1024i 6-13pL , Ricoh Gen5 7pL , Kyocera KJ4A 3,5pL | |||||

| Printhead Control | Printhead temperature and voltage are adjustable in software | |||||

| Ink Type | UV curable Ink | |||||

| Ink Reservoir | Refillable on the fly while printing / 2000ml | |||||

| Rip Software | PhotoPrint, ONYX and optionally Caldera | |||||

| Color Management | ICC based colors, curves adjustment, density adjustment | |||||

| File Format | Tiff, Jpeg, Postscript, Eps, Pdf | |||||

| Media Thickness | 1-7mm. | |||||

| Roll Weight | up to 100kg. | |||||

| Head Options | KM-1024i 6-13pL | Ricoh Gen5 7pL | Kyocera KJ4A 3,5pL | |||

| Resolution | 4-8pcs | 4-7pcs | 2-7pcs | |||

| 720 x 720 dpi | 600 x 600 dpi | 604 x 600 dpi | ||||

| 720 x 1080 dpi | 600 x 900 dpi | 604 x 1800 dpi | ||||

| 720 x 1440 dpi | 604 x 1200 dpi | |||||

| Printing Speed / per hour | ||||||

| Print Head Quantity | 4 heads 1 row | 4 heads 2 rows | 2 heads 1 row YMCK | 4 heads 1 row YMCK | ||

| Production Mode | 4 pass 42 sqm | 4 pass 42 sqm | 4 pass 60 sqm | 4 pass 80 sqm | ||

| Quality Mode | 6 pass 29 sqm | 6 pass 29 sqm | 6 pass 45 sqm | 6 pass | 60 sqm | |

| High Quality Mode | 8 pass 22 sqm | 8 pass 22 sqm | 8 pass 30 sqm | 8 pass | 40 sqm | |

| Print Colors | 4 colors (YMCK), 6 colors (Lc Lm YMCK). White and Varnish are optionals | |||||

| Drying System | Mercury UV Lamp with three power levels. Led UV Lamp is optional | |||||

| Medias | ||||||

| Flexible Medias | Paper, banners, wall paper, Mesh, faux leather, self-adhesive vinyl, One Way Vision, etc. | |||||

| Outdoor Life of Finished Printing | ||||||

| 3 years ( using Docan ink ) | ||||||

| Dimensions and Weight | ||||||

| Dimensions | 532 x 110 x 165cm. | Plywood packaged size: | 548 x 138 x 194cm. | |||

| Weight | 2500kg. | |||||

| Operation | ||||||

| Power Supply | 50/60Hz 220V(10%)>30A | |||||

| Operation Environment | 20°C to 28°C | |||||

| Humidity | 40% to 60% | |||||

| Connectivity | High speed USB 3.0 | |||||

| Warranty | ||||||

| 2 year limited warranty | ||||||