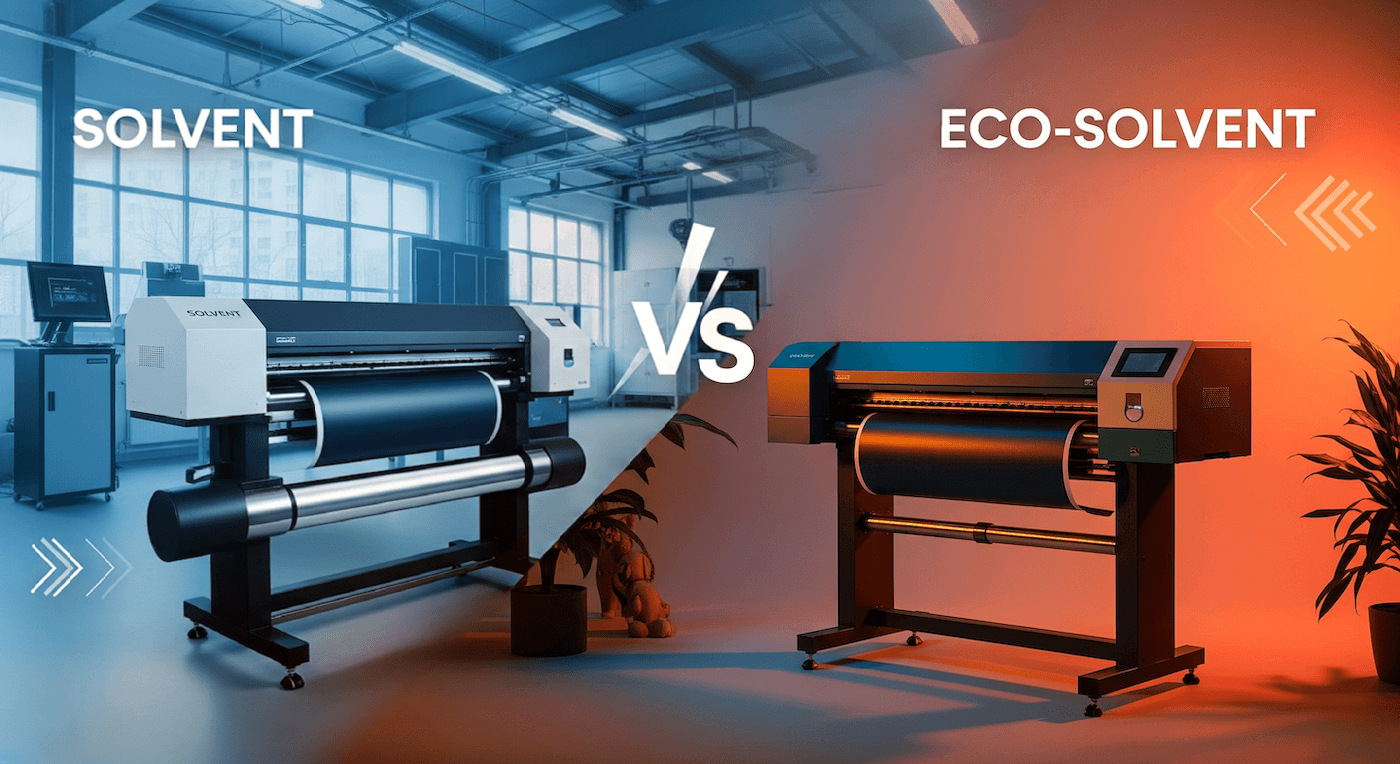

Differences Between Eco-solvent and Solvent Printing Machines

In the world of digital printing, choosing the right equipment is of critical importance in terms of production quality and efficiency. Ecosolvent and solvent printing machines, which are used especially in outdoor advertising, textile applications and promotional products, differ from each other in terms of their technological features and intended use. While both systems can print at high resolution, they show significant differences in terms of ink structure, environmental effects and durability. These differences directly affect both production costs and the longevity of the print.

The choice between Ecosolvent and solvent machines varies according to the target market, printing environment and environmental requirements. For example, the systems preferred for indoor banners and outdoor weather-resistant signs are quite different from each other. Therefore, in this article, we will discuss the basic differences, advantages and sectoral usage areas of both printing technologies in detail. Companies such as Pass Dijital, which provide services in this field in Türkiye, play an important role in directing this process with the right printing solutions suitable for customer needs.

Basic Technological Differences

When deciding between ecosolvent and solvent printing machines, technical details such as ink structure, print quality, machine life and maintenance needs should be carefully examined. Under this heading, we explain the differences that constitute the basic building blocks of these technologies.

Ink Type and Chemical Structure

Solvent printing machines use solvent-based inks that contain high levels of volatile organic compounds (VOCs). These inks penetrate the surface better and provide high durability against outdoor conditions. They are frequently preferred in signs, vehicle coatings and outdoor banners, especially due to their resistance to UV light, rain and wind. However, solvent ink requires good ventilation in the work area and is more environmentally risky because it contains high levels of chemicals.

In contrast, ecosolvent inks have a more environmentally friendly and low VOC structure. Therefore, they are ideal for indoor applications. Since they have low odor emission, they can be easily used in offices or small workshops. At the same time, being compatible with a wide range of materials such as PVC, vinyl, and canvas is another advantage of ecosolvent systems. However, they are a little more sensitive than solvent inks in terms of durability.

This difference requires companies to make the right choice according to their production areas and target markets. For example, manufacturers such as Pass Digital provide their customers with both technical support and product recommendations according to sectoral needs.

Print Quality and Color Accuracy

Ecosolvent printing machines stand out in terms of vividness and detail, especially in indoor visuals. Thanks to the ability to print at high resolution, it is possible to obtain results close to photographic quality. This feature provides a great advantage in applications such as in-store posters, fair visuals, and decorative panels. Color transitions are smoother and print details appear much clearer.

Solvent printing machines are generally preferred for larger format prints. Since they are used outdoors, durability is more important than color accuracy. However, with the print head technologies that have developed in recent years, high-resolution results can be achieved in solvent systems as well. Nevertheless, ecosolvent systems are more successful in jobs that require very fine details or soft transitions.

Correct adjustment of color profiles directly affects print quality in both systems. The ICC profiles used, software support and pre-press preparation processes make a difference, especially in commercial prints. For this reason, businesses working with professional printing machines pay special attention to color management, regardless of the system they work with.

Machine Usage and Maintenance Processes

The operating costs of printing machines are not limited to energy consumption. Many parameters such as maintenance frequency, head cleaning and stable operation of the ink system directly affect daily operations. Solvent printing machines require regular maintenance because they work with inks with high chemical content. Print head clogging, nozzle errors or ink drying can often occur. This causes users to need more technical knowledge.

Ecosolvent systems work more stably. Especially in models developed to be end-user friendly, automatic cleaning systems require less user intervention. This provides a serious advantage, especially for small businesses. In addition, the time spent at the machine decreases and the production speed increases. However, these systems also requireIt should not be forgotten that it requires maintenance with herbs.

For both systems, the technical support and spare parts provided by the manufacturers are of critical importance. At this point, reliable suppliers such as Pass Digital allow users to continue production without experiencing any problems in terms of both after-sales service and technical knowledge.

Areas of Use and Sectoral Preferences

Ekosolvent and solvent printing machines are preferred in different sectors according to the targeted application area and conditions of use. While precision, health criteria and aesthetics are at the forefront in interior projects, durability, longevity and cost control are priorities in exterior spaces. The selection of printing technology according to the needs of the sectors is also a critical factor in terms of return on investment.

Advertising and Outdoor Applications

Outdoor advertising is one of the areas where solvent printing machines are used most intensively. In applications such as billboards, vinyl banners, tarpaulin prints, vehicle wraps and building facade cladding, the high resistance provided by solvent inks to external factors offers a great advantage. The fact that the print does not deteriorate against sunlight, rain, humidity and sudden temperature changes ensures that advertising messages reach the target audience permanently.

Solvent systems can also work in very large print sizes without any loss of performance. This means that brands can attract attention with large-scale visuals in open areas. In such projects, durability is more important than print quality, which highlights solvent technology.

However, ecosolvent systems are preferred in indoor advertising applications. Store displays, roll-up systems, exhibition stands and POS (point of sale) materials can be produced with ecosolvent printing in a higher resolution, more vivid and odorless way. Since image quality and customer experience are directly related in these areas, ecosolvent systems are a more suitable choice.

Indoor and Outdoor Use

Indoor applications are mostly worked with ecosolvent systems because they require health and odor sensitivity. The low VOC content of the inks is safer for personnel and customers working in indoor areas. Some of the areas of use of this system are in-office directional signs, decorative canvas paintings, indoor posters and fair stands. In addition, when the fade period of the prints is longer, visual arrangements in indoor areas require less revision.

When it comes to outdoor use, solvent printing technology comes to the fore. External factors such as UV rays, wind, snow and rain ensure that the print remains intact for a long time thanks to the permanent structure of the solvent-based ink. For this reason, products resistant to harsh conditions such as construction site panels, highway advertisements and outside fair promotions are produced in solvent machines.

Today, some hybrid solutions are also being developed. Some companies offer flexibility by offering machines that meet indoor and outdoor requirements in a single system. However, in each case, choosing the appropriate system for the application to be used is critical in terms of efficiency and quality.

Sustainability and Environmental Impacts

Sustainability is an increasingly prominent issue in the digital printing sector. In this context, ecosolvent printing systems are the primary choice for companies that want to make environmentally friendly production. Advantages such as low chemical emissions, compatibility with recyclable printing materials and energy efficiency play an important role in reducing the environmental footprint. These features are especially preferred by institutions that adopt green production policies.

On the other hand, solvent systems can have a more intense environmental impact due to VOC emissions and high chemical content. Long-term use can pose a risk to both personnel health and environmental standards. For this reason, solvent ink use is controlled by certain standards in many countries. These effects are tried to be minimized with compatible filter systems, ventilation solutions and special work areas.

Companies operating in the sector such as Pass Dijital contribute to the development of not only high-quality but also environmentally friendly printing processes by offering special solutions to businesses with environmental sensitivity. Sustainability is no longer just a preference, but has become a corporate responsibility.

Investment Cost and Operating Efficiency

Investment in a printing system is not limited to the cost of the device. Factors such as consumables, energy use, maintenance needs and production capacity also determine the total operating cost. Therefore, businesses should focus not only on the purchase price but also on long-term profitability when choosing the right technology.

Initial Investment Costs

Solvent printing machines generally have higher initial investment costs because they are suitable for larger formats and industrial scale production. These machines are more durable, have higher capacity and are generally designed for long-term projects. Therefore, while large-scale advertising agencies or outdoor printing centers prefer solvent systems, they should also have a work volume that can amortize this cost.

Ecosolvent systems are more compact and have a price level that is accessible especially for small and medium-sized businesses. Since there is a wide product range from office type machines to medium format systems, it is easy to find an option suitable for the scale of the business. In addition, some ecosolvent models offer quite economical solutions in the long term thanks to their low energy consumption and software optimizations.

However, looking only at the device price can be misleading. Factors such as the output capacity required by the business, production frequency and customer profile should also shape the investment decision. At this point, companies like Pass Dijital provide guidance to users in choosing the right machine that suits both their budget and their intended use.

Consumables and Consumable Expenses

Consumable items such as ink consumption, print head life, spare parts supply and printing media are the most important factors affecting the total operating cost. Inks used in solvent machines may generally be cheaper per liter; however, due to high consumption rates and the need for regular maintenance, the total cost may increase over time. In addition, the variety of materials used in solvent systems is more limited and extra processing may be required for some special surfaces.

In Ecosolvent systems, although the ink seems more expensive, the consumption amount is more controlled. In addition, thanks to systems optimized for high print quality, the waste rate is lower. This allows the business to manage stock and production control more efficiently in the long term. In addition, the fact that environmentally friendly inks are compatible with recycling provides advantages in terms of both cost and sustainability.

The choice of printing medium (vinyl, canvas, foil, etc.) also affects costs. Ecosolvent machines offer more options in terms of cost control since they have more flexible media options. With the right media usage, both quality is not compromised and operating costs are balanced.

Comparison of Productivity and Production Speed

Production efficiency is one of the main ways to gain competitive advantage in the printing sector. Solvent machines generally have the capacity to print at higher speeds. For large-scale jobs, this means time savings. However, this speed can sometimes cause loss of detail. This can have negative consequences, especially in quality-sensitive indoor applications.

Although ecosolvent systems operate at slightly lower speeds, they maintain print quality and provide stable production. In cases where the target market is qualified and detailed jobs, the efficiency of these systems is higher. In addition, thanks to less maintenance and automation features, operator intervention is minimized, which saves time.

Another important point is the management of job delivery times. In ecosolvent systems, the drying time after printing is shorter, which allows products to be delivered faster. Since solvent printing requires additional processes such as drying time and lamination, the job delivery time may be longer. This difference can directly affect the customer satisfaction of the business, especially during busy order periods.

Frequently Asked Questions

- What is the most basic difference between ecosolvent and solvent printing machines?

The most basic difference is in the ink structure used. Solvent inks are more durable and suitable for outdoor use; ecosolvent inks are more environmentally friendly, odorless and ideal for indoor applications. - Are solvent inks harmful to health?

Since solvent inks contain high VOCs, they can be harmful to health when exposed for long periods. Therefore, it is recommended to work with good ventilation systems. - Can ecosolvent machines be used for outdoor printing?

They can be used in short-term outdoor applications that are not exposed to direct sunlight. However, solvent systems are more suitable for jobs that will be exposed to outdoor conditions for long periods. - Which system has a longer lifespan?

Both systems can have a long lifespan when properly maintained. However, since solvent machines are produced for more industrial use, they can last longer in high-volume jobs. - Which sectors are solvent, whichi prefer ecosolvent?

While sectors such as advertising agencies, vehicle coating companies, and outdoor advertising prefer solvents, interior decoration, exhibition materials, and store visual arrangements prefer ecosolvent systems.