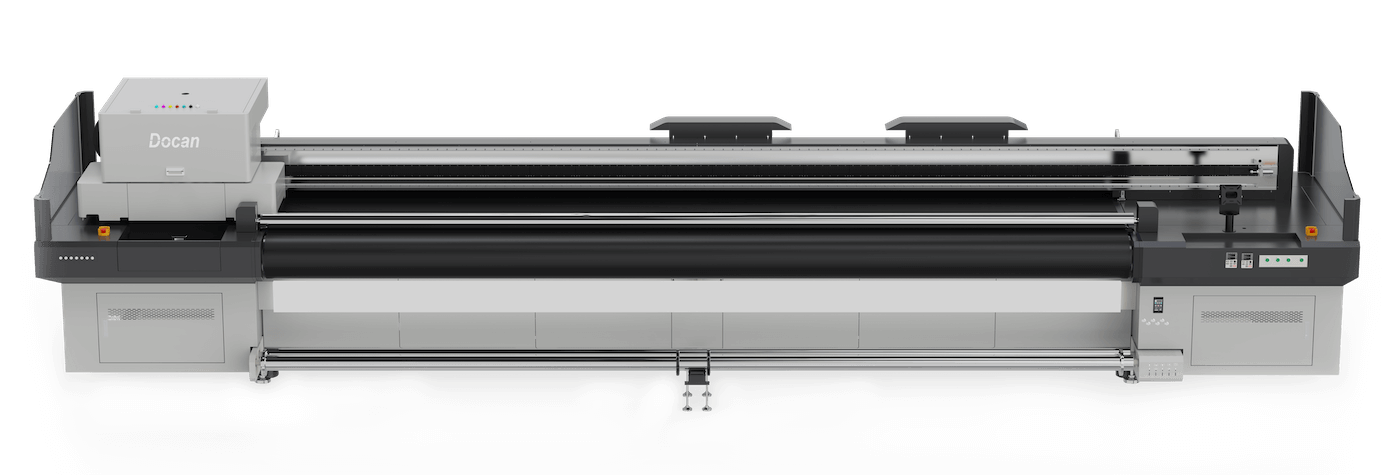

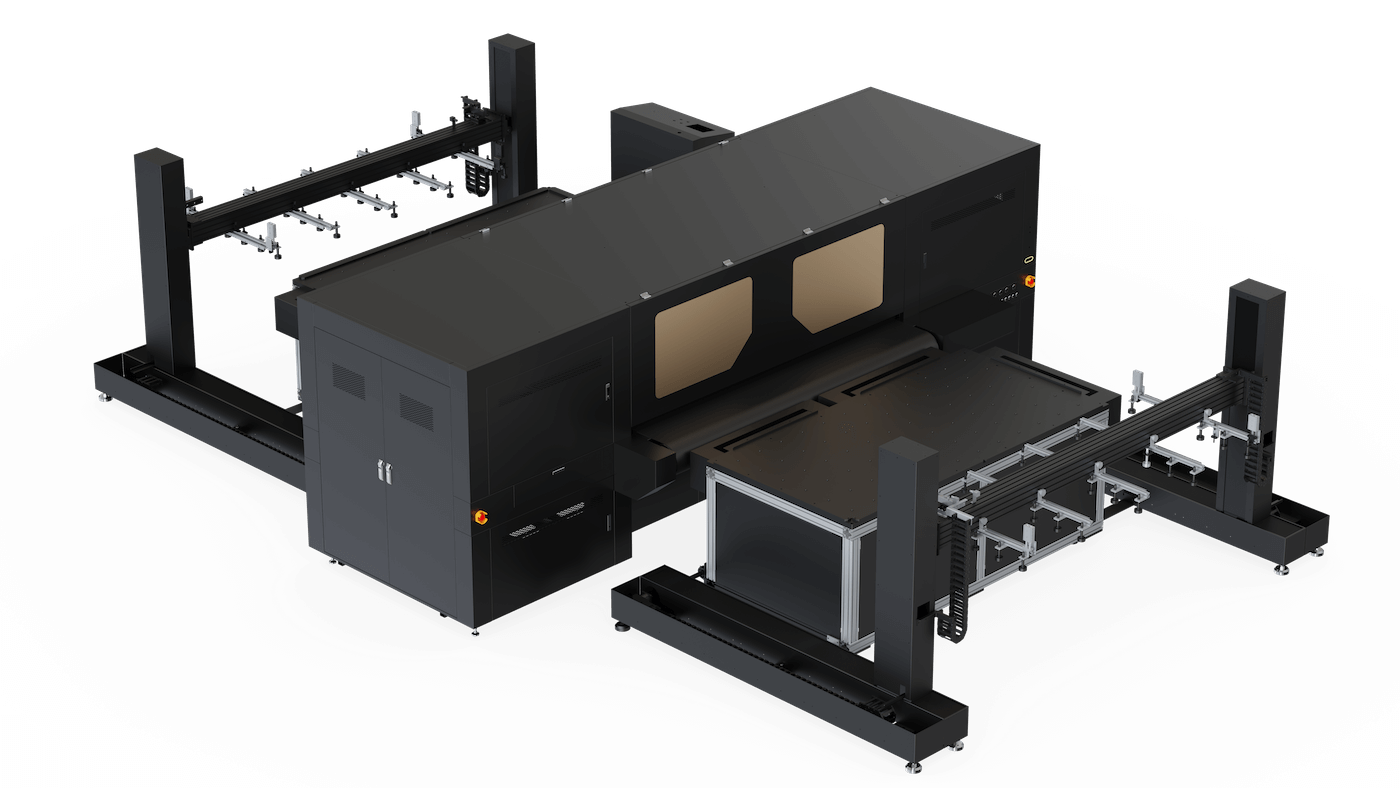

Docan UV R3200

Industrial UV Roll Printing Machine Roll

High Speed UV Roll Printer

Quality printing for roll materials, can print UV at a speed of 95m² per hour with 3 rows of Konica print heads!

The new generation industrial roll printer combines high precision, speed and multi-material compatibility, offering unlimited possibilities for your creativity.

3.2 meters wide, multi-material size compatibility.

Print Head ArrangementKonica print head maximum 3 rows.

Roll PrintingFocus on roll printing, overcome print length barriers.

Key Technology Features

Discover the revolutionary technology of R3200, unique printing experience experience.

Modular Design Economical Production Tool

Solves equipment budget problems of small and medium-sized enterprises, industrial production performance, economical investment.

- 3.2 meters printing width, modular design, durable core components tested in the market

- Supports multiple materials such as wood, metal, leather, reduces customers' equipment investment

Pneumatic Cylinder Mechanism, High Precision Automation

One-touch pneumatic cylinder control, fast response to different material and process requirements (hard/soft material transitions), increase equipment versatility, adapt to high-speed production.

- Material flattening: Wrinkles or looseness on the fabric surface are removed with main and auxiliary cylinders, the material remains flat while transporting, no printing slippage or blurring is prevented

- Tension stability: The printing force and material tension work in harmony to reduce slippage or deviation, maintaining continuous printing precision

- Improves printing quality: The distance between the flattened fabric and the print head remains stable, the ink drop deviation caused by material fluctuation is reduced, color uniformity and pattern clarity are increased

Water-Cooled Platform + Vacuum Suction, Material Deformation and Corrosion Prevention

The negative pressure with the water-cooled platform and vacuum suction system stabilizes the material and increases heat dissipation, preventing double slippage and deformation.

- Regulates the heat accumulation between the material and the print head during printing, prevents thermal deformation, and maintains material uniformity.

- Stabilizes ink curing: The heat effect on ink properties is reduced with temperature control, drop position and curing uniformity are ensured

- High-efficiency water cooling system with high capacity suitable for continuous production

Technical Specifications

Learn the detailed technical specifications of R3200, meet your professional needs.

| Print Area | 3200mm |

| Print Height | Maximum 20mm |

| Print Resolution | Maximum 726*2400dpi |

| Print Speed | Konica 1024A(6PL): 4Pass (3 Rows):76~95m²/hour 6Pass (3 Rows):55~63m²/hour 8Pass (3 Rows):35~40m²/hour Ricoh Gen6(5PL): 4Pass (3 Rows):50~58m²/hour 6Pass (3 Rows):41~48m²/hour 8Pass (3 Rows): 27~32m²/hour Kyocera(3.5PL): 4Pass (1 Row):30~38m²/hour 6Pass (1 Row):25~32m²/hour 8Pass (1 Row): 20~25m²/hour |

| Printhead Configuration | Konica 1024A(6PL), Ricoh Gen6(5PL), Kyocera(3.5PL) |

| Number of Printheads | Konica 1024A(6PL):4~18pcs Ricoh Gen6(5PL):2~9pcs Kyocera(3.5PL):2~7pcs |

| Ink Colors | CMYK/LC/LM+B |

| Curing Method | UV LED Light |

| Image Format | TIFF, JPEG, EPS, PDF |

| RIP Software | SAI/ONYX/Caldera |

| Power Requirements | AC220V 50/60Hz 10KW 45A |

| Environmental Requirements | Temperature: 20℃~28℃ Humidity: 40%~60% |

| Ink Tank Capacity | 2L |

| Device Dimensions | 5320*1500*1700mm |

| Equipment Weight | 2595kg |

Request a Quote

Please fill out the form to receive a personalized price quote for the product you have viewed. Our sales team will get back to you as soon as possible.