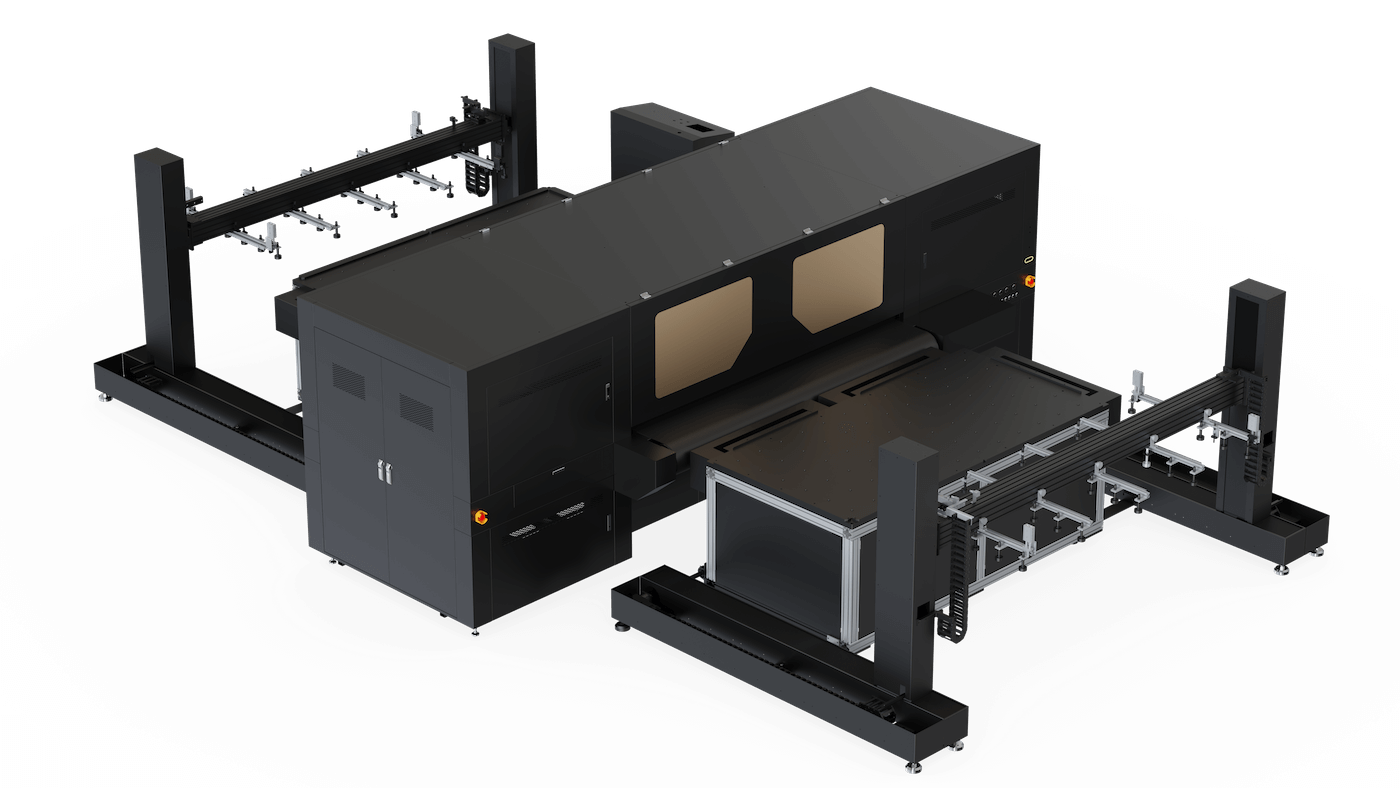

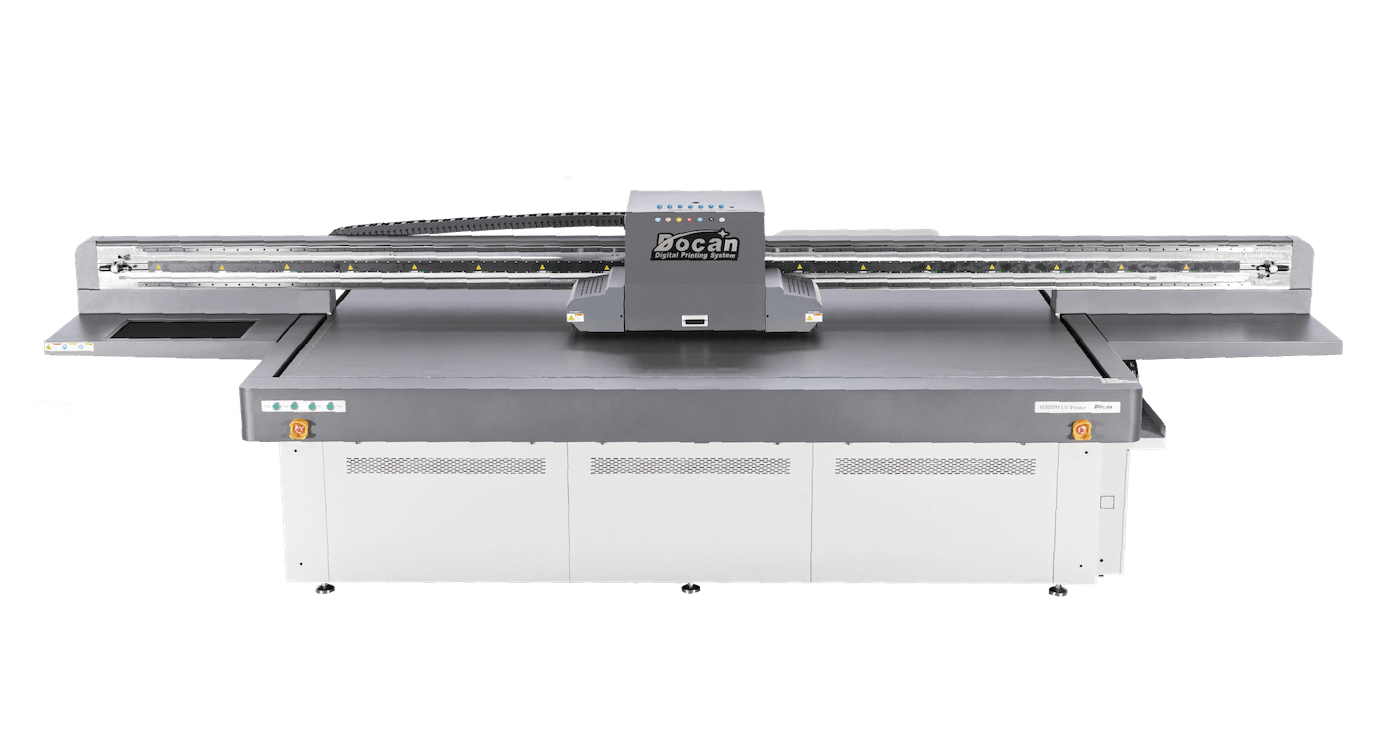

Docan UV R5200

Roll to Roll UV Printing Machine

Focus on Large Format, Mature Printing Technology

R5200 inherits DOCAN's high-quality production technology. It features a fully welded body structure, providing superior rigidity and stability at high speeds. With 4-row Konica wide configuration, it can print UV at a speed of 124m² per hour!

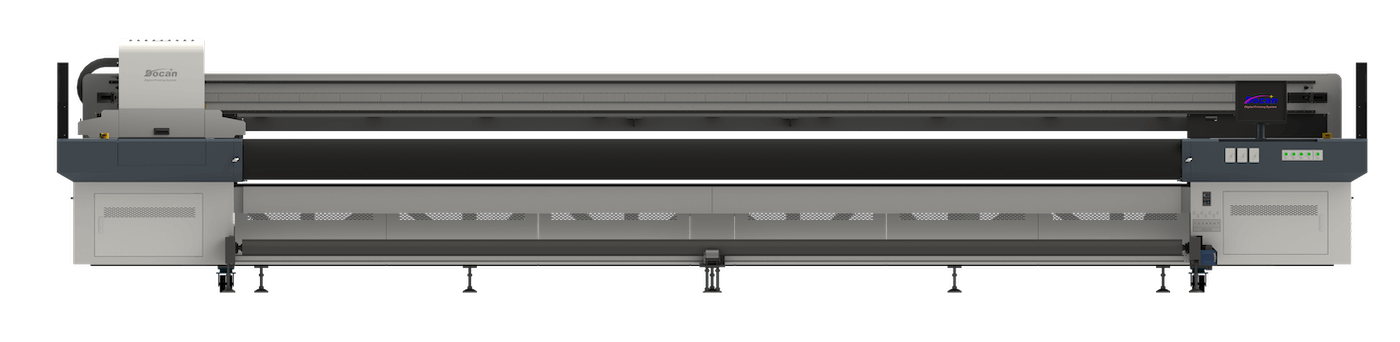

5.1-meter wide high-quality roll machine, high-precision automatic winding system, millimeter edge deviation, perfect alignment.

5.1-meter width offers perfect wide format

Printhead ArrangementKonica printhead maximum 4 rows.

Roll PrintingFocus on roll printing, break through print length barriers.

Key Technology Features

Discover the revolutionary technology of R5200, experience an unprecedented printing experience.

5.1-meter Print Width, Industrial Heavy Duty Printer

Designed for super-wide material handling, reducing the need for splicing and material waste.

- Wider print area in one go: Covers wider materials, increases application compatibility

- Production efficiency is greatly increased, high capacity output with up to 4 row print head layout

One-touch pneumatic printing cylinder mechanism, high-precision automation

One-touch pneumatic cylinder control provides fast response to different material and process requirements (hard/soft material transitions), increases equipment versatility, and adapts to high-speed production.

- Material flattening: Wrinkles or slack on the fabric surface are removed with the main and auxiliary cylinders, the material remains flat while being transported, and printing slippage or blurring is prevented

- Tension stability: The printing force and material tension work in harmony to reduce slippage or deviation, and maintain constant printing precision

- Improves printing quality: The distance between the flattened fabric and the printing head remains stable, ink drop deviation caused by material fluctuation is reduced, and color uniformity and pattern clarity are increased

Water-cooled platform + vacuum suction, prevents material deformation and corrosion

The material is fixed with the water-cooled platform and vacuum suction system, and the heat dissipation is increased, providing double slip and deformation prevention effect.

- Prevents thermal deformation by adjusting the heat accumulation between the material and the print head during printing, maintains material smoothness

- Stable ink curing: The heat affecting the ink properties is reduced with temperature control, and precise placement and homogeneous curing of ink drops are ensured

- Efficient heat dissipation with water cooling suitable for high-capacity production needs, adapts to high-speed continuous production

Technical Specifications

Learn the detailed technical specifications of R5200, meet your professional needs.

| Print Area | 5100mm |

| Print Height | Maximum 20mm |

| Print Resolution | 726×2400dpi |

| Print Speed | Konica 1024A(6PL):4Pass(4 Rows):100~124m²/hour 6Pass(4 Rows): 72~84m²/hour 8Pass(4 Rows): 52~64m²/hour Kyocera(3.5PL):4Pass(2 Rows): 88~100m²/hour 6Pass(2 Rows): 72~85m²/hour 8Pass(2 Rows): 50~65m²/hour |

| Printhead Configuration | Konica 1024A(6PL), Kyocera(3.5PL) |

| Printhead Number | Konica 1024A(6PL):4~28 pcs Kyocera(3.5PL):2~14 pcs |

| Ink Colors | CMYK/LC/LM+B |

| Curing Method | UV LED Light |

| Image Format | TIFF, JPEG, EPS, PDF |

| RIP Software | SAI/ONYX/Caldera |

| Power Requirements | AC220V 50/60Hz 10KW 45A |

| Environmental Requirements | Temperature: 20℃~28℃ Humidity: 40%~60% |

| Ink Tank Capacity | 5L |

| Device Dimensions | 8150mm × 2000mm × 1950mm |

| Equipment Weight | 6435kg |

Request a Quote

Please fill out the form to receive a personalized price quote for the product you have viewed. Our sales team will get back to you as soon as possible.