High Quality and Fast Production with UV Printing Machines

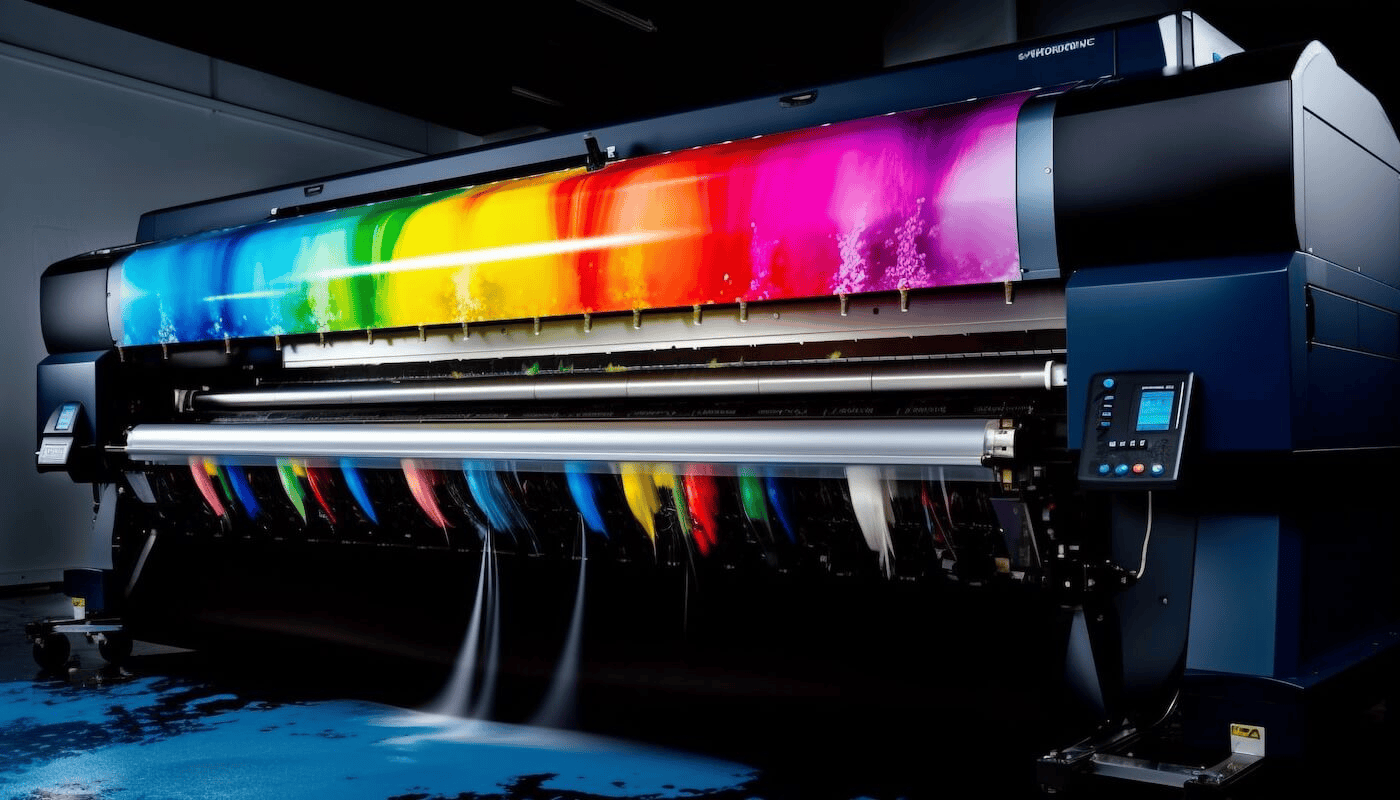

UV printing machines are among the technologies that have virtually revolutionized the digital printing world. With features such as fast drying, vibrant colors, and versatile surface usage, not only printers but also advertising agencies, manufacturers, and creative industries have taken these machines on their radar. UV printing machines are expanding the boundaries in many areas where traditional printing techniques are limited. These machines, which are preferred in countless sectors from signage production to packaging design, from personal gift products to artistic prints, also play a key role in the digitalization process of modern businesses.

Pass Digital, one of the companies that has successfully introduced this technology to users in the Turkish market, stands out with its quality product range and technical support. Offering special solutions to both entrepreneurs and large-scale businesses, Pass Digital has become a reliable partner in UV printing technology.

What is UV printing technology and how does it work

UV printing technology can be defined as the evolved form of digital printing; In this system, the ink applied to the surface is instantly hardened and fixed with UV (ultraviolet) light. This method is much faster and more effective than traditional drying processes because it allows the ink to integrate with the surface. One of its most striking advantages is that it can print directly on many different materials - such as glass, metal, leather, plastic and wood. Thanks to this technology, production can be done without the need for intermediate layers, lamination or waiting for drying time. UV printing not only offers speed and flexibility; it also provides clear details, high color accuracy and low-emission production that does not harm the environment. For this reason, it has become one of the preferred printing methods in both creative projects and industrial applications.

Fundamentals and development process of UV printing

UV printing technology gets its name from the ultraviolet (UV) rays it uses. In this system, specially formulated UV inks are sprayed onto the surface and then instantly dried with UV rays. Since this drying process takes place in almost seconds, it both saves time and eliminates the risk of smearing the print. This technology, which was first used commercially in the early 2000s, emerged as an environmentally friendly alternative to traditional solvent-based printing techniques.

Environmental advantages such as the absence of solvent odor and the minimization of VOC (volatile organic compound) emissions have made UV technology even more attractive. Throughout the development process, print quality has increased, print heads have become more sensitive, and ink options have expanded. Today, UV printing can produce high-quality results on almost every material, such as glass, metal, wood, acrylic, PVC, and leather.

UV ink and drying technologies

One of the most important elements at the heart of UV printing is specially formulated UV inks. These inks do not dry with air like classic inks. On the contrary, they become solid by chemically reacting with the strong ultraviolet rays emitted by UV lamps immediately after the ink is sprayed. This allows the ink to adhere completely to the surface.

There has also been great progress in the sector in terms of drying technologies. Since the first generation UV lamps emitted high heat, they could cause problems on some sensitive materials. However, today, thanks to LED UV systems, lower-heat, more energy-efficient and environmentally friendly solutions are produced. This makes it possible to work on a wider range of surfaces.

Another advantage of this system is that since there is no waiting for a drying period, post-printing processes (cutting, assembly, packaging, etc.) can be moved on much faster. This provides a great advantage especially in production lines where time is critical.

Differences between traditional printing and UV printing

Traditional printing systems generally use solvent, water-based or latex inks, and these inks take time to dry. The ink evaporates during the drying process, and this can cause harmful gases to be released into the environment. In addition, drying of the ink on some surfaces is either difficult or impossible.

In UV printing machines, such limitations are almost non-existent. Since drying is instantaneous, the production process is both faster and more efficient. In addition, UV ink becomes more resistant to water, scratches and sunlight as soon as it adheres to the surface. This is a great advantage for prints to be used outdoors.

For example, consider an advertising sign: When produced with traditional printing, this sign may fade, crack or run in the rain over time. However, signs made with UV printing are much more durable and retain their first-day vibrancy. This difference makes UV technology indispensable, especially in outdoor applications.

Pass Digital, offers world-class solutions to printing professionals in Türkiye by offering the most up-to-date versions of this technology to users. It also ensures that users get maximum efficiency from the system with technical support and training services.

Where are UV printing machines used

UV printing machines are suitable for use in many sectors thanks to their versatility. UV technology offers both creative solutions and speeds up production processes in areas where classic digital printing machines are limited. Especially thanks to their ability to print on different surfaces, these machines can be integrated into many different sectors such as advertising, industry, architectural decoration and personal product production.

Advantages such as surface-independent printing ability, high-resolution output, color vibrancy and long-lasting use stand out in the widespread use of UV technology. In addition, since the print does not have to be left to dry as in solvent-based systems, work processes become more efficient. For these reasons, interest in UV printing machines is increasing day by day both in small workshops and in giant production facilities.

UV printing in the advertising and promotion sector

The advertising sector is one of the areas where UV printing technology is most actively used. Many materials such as signs, posters, promotional products, indoor and outdoor billboards can be produced with UV printing. The durability of materials used especially in outdoor advertising is of great importance. Thanks to the resistance of UV ink to sunlight, water and scratches, advertising products have a much longer life.

In addition, digital printing agencies have to respond very quickly to customer demands. UV technology responds to this need one-on-one with its fast production capacity. Instead of drying times that last for hours, products ready for printing can be prepared in a few minutes. This provides agencies with a serious time and cost advantage.

At this point, Pass Digital draws attention with its UV printing machines specially developed for advertising agencies. It provides flexibility to the sector by offering desktop solutions for both industrial machines for high-volume printing and companies that will produce small-scale promotions.

UV printing applications in industrial production

It is quite impressive to see that UV printing is not limited to advertising. For companies that do industrial production, this technology has become a solution that can be integrated into mass production lines. For example, the automotive sector can prefer UV printing for marking and adding visual details to vehicle parts. Direct printing of brand logos and technical information on electronic products can also be done with UV technology.

In the furniture sector, patterns, logos or patterns can be easily printed on surfaces such as wood, glass or MDF. While such applications are either more costly or take longer in traditional techniques, decorative products can be prepared in minutes with UV printing machines.

The biggest advantage of this system for industrial companies is its compatibility with automation. By integrating printing systems into the production line, maximum efficiency can be achieved with minimum manpower. LED UV systems in particular also score extra points in terms of sustainability with their low energy consumption and long lamp life.

UV solutions for personalization and gift products

In recent years, the increasing demand for personalized products has made UV printing technology indispensable for small enterprises and online sales platforms. Products such as mugs, key chains, phone cases, stone prints, and agendas can be customized quickly and in high quality with UV technology.

Especially for e-commerce sites and gift manufacturers, these machines minimize stock costs as they allow production to be made to order. When a customer wants to print their name or a special message on a product, the personalized product can be delivered within minutes with the UV machine.

UV machines used in this segment are generally more compact, which is quite advantageous for small workshops or home-office users. Since investment costs are also lower, it creates an attractive business opportunity for many entrepreneurs.

Pass Digital, which provides services in this field, stands out with its desktop UV printer solutions so that small businesses can also print in high quality. It offers entrepreneurs a safe start with easy-to-use interfaces, a wide support network and economical consumable options.

What to consider when buying a UV printer

Buying a UV printer is a serious investment, especially for those who are new to the sector. Therefore, when making a choice, not only the price but also many factors such as quality, technical support, ink cost, printing speed, available space and service network should be evaluated. WhateverAlthough UV printing machines offer solutions in many areas with the technology they offer, if the right choice is not made, the investment can quickly become inefficient.

Choosing a model that suits the needs, especially with the consultancy of companies specialized in this field such as Pass Dijital, is critical for the long-term success of businesses. The machine to be invested in should be flexible enough to meet not only today's needs but also future operations. Here are the basic elements to consider when purchasing a UV printing machine:

Machine type and printing area selection

UV printing machines can be found on the market in many different models and sizes. While some models only print on flat surfaces, others can also print on cylindrical or complex surfaces. Therefore, it should be determined which type of products will be printed first. For example, if you will only work on flat-surface billboards, plexiglass panels or metal surfaces, flatbed UV printing machines may be ideal for you.

However, if you have a wide range of products—for example, if you want to personalize mugs, phone cases, and wooden products at the same time—then hybrid machines that can print on both flat and curved surfaces should be preferred. The size of the products to be printed is also a very important criterion. If you are planning to print on large-sized materials, you should prefer machines with a wide printing area.

Pass Digital offers machines specially developed for different production scales and printing needs. Whether you are looking for a desktop UV printer or an industrial-level flatbed system... The company is quite rich and user-friendly in terms of product range.

Comparisons of cost, speed, and efficiency

Of course, investment cost is an important factor, but it should not be the sole determinant. Because low-priced machines can usually create higher operating costs in the long run. For example, ink consumption is much higher in some machines. In addition, the life of the print heads may be short or your work may be interrupted in the event of a technical failure since the service network is limited.

Therefore, when buying a UV printing machine, not only the price but also the total cost of ownership should be taken into consideration. These cost items include:

-

Ink consumption rate

-

Electricity consumption

-

Printing speed (how many square meters can be printed per hour)

-

Operator requirement

-

Periodic maintenance and spare parts costs

Printing speed is also a very critical issue. Especially if you are receiving high-volume orders, a slow-running machine can disrupt your work. Therefore, you should calculate how many products you can print per minute by considering your production volume.

Pass Dijital offers its customers such comparisons in detail, allowing them to choose the most suitable machine. It also aims to provide the most efficient return on your investment by offering ideal solution suggestions according to your production capacity.

Technical service and spare parts support

The work does not end after purchasing a UV printing machine. On the contrary, the real important process begins after this: technical service support. Because these machines are digital systems that operate with high precision and may require maintenance, calibration or part replacement over time.

When you work with brands that do not have a good technical service network, every failure you experience can lead to long-term production loss. This negatively affects customer satisfaction and business continuity. In addition, some companies may have problems in supplying spare parts and consumables. This situation poses a risk for your business.

Therefore, one of the most important criteria you should pay attention to when purchasing a machine is the company's after-sales support structure. How fast is technical support provided? Can spare parts be easily obtained? Is remote support possible? All of these are critical questions that need to be asked.

Pass Dijital, one of the reliable brands in this regard, has a wide service network and instant support team throughout Turkey. It also offers its users many advantages such as technical training, spare parts supply and remote connection and fault detection. In this way, machines can be operated with maximum efficiency and minimum downtime.