New Perspectives and Strategic Approaches in the World of UV Printing

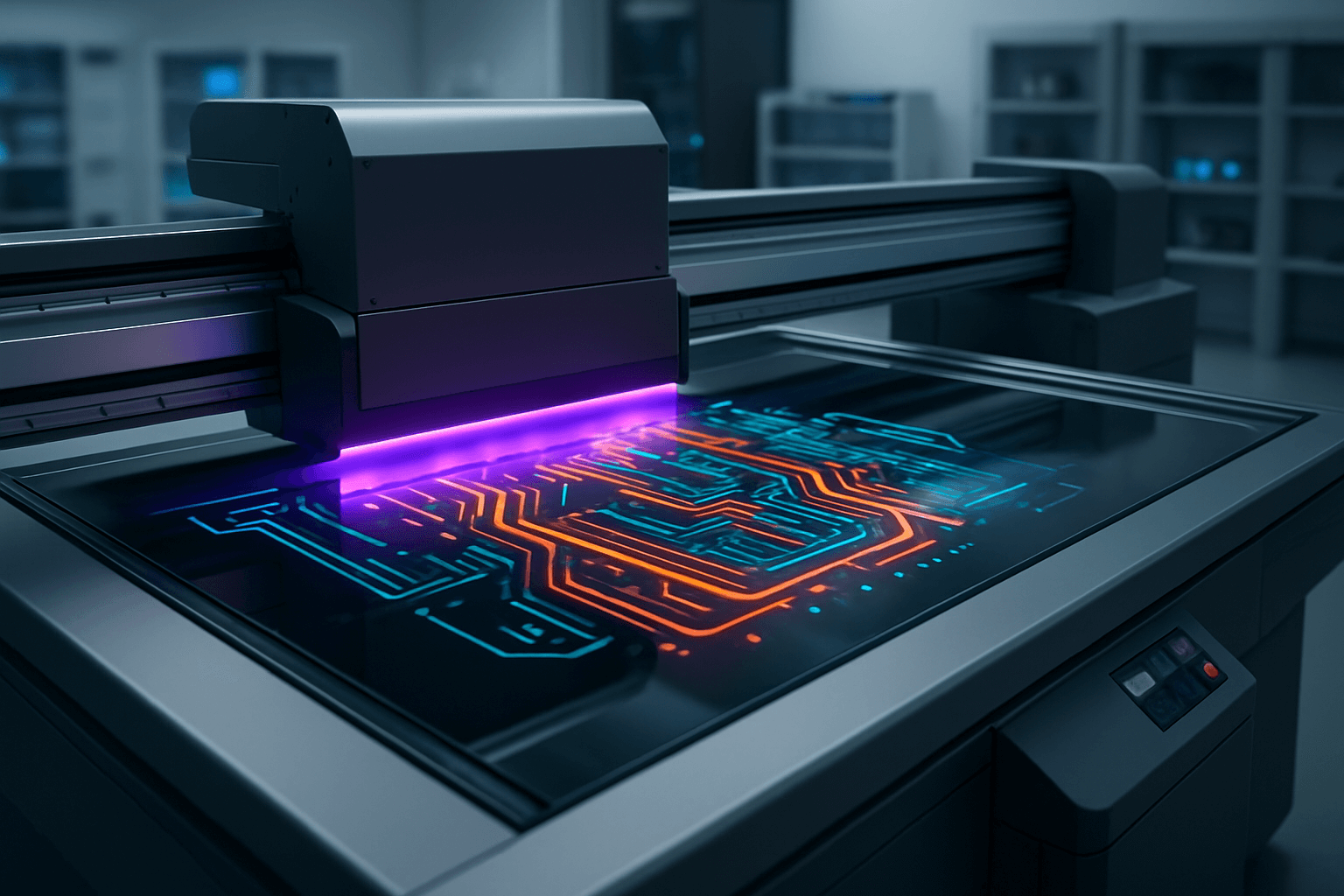

UV printing technologies have attracted growing attention in recent years not only for their print quality, but also for the strategic advantages and flexible production capabilities they offer. Going beyond the limitations of traditional printing methods, this technology provides businesses with significant competitive power in terms of speed, durability, and surface versatility. Today, UV printing is no longer just a production technique; when structured correctly, it becomes a strong value proposition for brands.

Thanks to advanced curing systems, next-generation printheads, and software-driven production processes, UV printing has become an accessible solution for businesses of all sizes. The increasing demand for personalized production, low-volume jobs, and fast delivery has made this technology almost indispensable. However, the real differentiator at this point is not merely using the technology, but understanding it correctly, positioning it in the right areas, and integrating it into long-term strategies.

This article provides a holistic perspective on UV printing, from its technical depth to sectoral applications, from investment decisions to future projections. The goal is to present a fluent and strategic framework rather than fragmented information, offering guiding content for those who want to take solid steps in the world of UV printing.

Technical Depth and Innovation-Focused Topics

The true potential of UV printing technologies emerges through a proper understanding of technical details. Every component—from curing systems and printheads to ink structure and software integration—directly affects final product quality and production efficiency. For this reason, technical innovations should be considered not merely as “novelties,” but as strategic investments.

The Future of LED Laser and Low-Energy Curing Technologies

Traditional UV lamps have served the industry for many years; however, energy consumption, heat-related issues, and maintenance costs have made alternative solutions inevitable. LED laser-based curing systems are changing the rules of the game at this point. Their ability to operate with significantly lower energy consumption provides major advantages in terms of both environmental sustainability and operational costs.

Low-energy curing technologies make it possible to print on heat-sensitive surfaces in particular. Reduced deformation risk on materials such as wood, thin plastics, or special coatings directly increases product diversity. This makes UV printing attractive not only for industrial production but also for boutique and design-oriented projects.

Looking ahead, LED laser systems are expected to combine with software-driven automation to offer smarter curing processes. These developments increase production speed while making quality standards more predictable.

Embossing and Special Effect Production with 3D Textured UV Printing

One of the most striking innovations in UV printing is 3D textured printing applications. Thanks to this technology, surfaces create perception not only visually but also tactually. Embossed lettering, textured patterns, and multi-layer effects create a strong perception, especially for premium products.

3D UV printing transforms storytelling into a physical experience for brands. It offers a wide range of applications, from business cards and packaging to decorative panels and promotional products. The key advantage here is achieving these effects without molds or additional processing steps.

When planned correctly, 3D textured UV printing has the potential to create high-margin niche jobs. Therefore, this technology should be seen not just as an aesthetic feature, but as a value-adding tool.

Analysis of Epson i3200, Ricoh Gen5 Gen6, and Konica Minolta 1024i Printheads

The printhead is the heart of a UV printing machine. Epson i3200, Ricoh Gen5 and Gen6, and Konica Minolta 1024i models are among the most preferred solutions in the industry. The droplet size, speed, and durability characteristics each offers address different production needs.

While the Epson i3200 stands out with high resolution and stable performance, Ricoh Gen5 and Gen6 provide a long-lasting and reliable structure for industrial production. Konica Minolta 1024i is preferred for speed and large-area printing. The key question here is not “which is the best?” but rather “which one fits my business model?”

Choosing the right printhead reduces maintenance costs and preserves production quality over the long term. This decision is a critical factor that directly affects the success of a machine investment.

Sectoral Applications and Niche Market Opportunities

The strength of UV printing lies in its ability to adapt easily to different industries. Businesses that develop sector-specific applications rather than standard solutions gain several steps of advantage over the competition. Niche markets, in particular, offer significant opportunities for UV printing.

The Rise of UV Printing in Architecture and Interior Design

In architectural and interior design, personalization is no longer a luxury but an expectation. UV printing offers designers a wide field of freedom by enabling direct printing on surfaces such as glass, ceramic, wood, and metal. Wall panels, decorative glass, and custom-designed furniture surfaces are among the most common application areas of this technology.

The durability of UV printing provides long-lasting solutions for interior applications. Prints resistant to fading preserve the aesthetic value of projects for many years, offering a major advantage for both designers and end users.

For businesses operating in this field, UV printing represents high-budget, project-based work. When the right partnerships are established, architectural applications can create a sustainable revenue model.

The Speed and Personalization Advantage of UV Printing in the Packaging Industry

The packaging industry is one of the areas where speed and flexibility are most critical. UV printing saves time by enabling production without waiting for drying periods. In addition, low-volume and personalized packaging solutions create a significant differentiation for brands.

UV printing offers an ideal solution especially for product launches, limited-edition collections, and campaign packaging. The ability to produce without mold costs also simplifies trial and testing processes.

At this point, the approach of companies with high sectoral awareness such as PASS Dijital clearly demonstrates how UV printing can be transformed into a strategic advantage in packaging.

The New Competition Introduced by UV DTF Technology to Traditional UV Printing

UV DTF technology transforms the advantages offered by UV printing into a more portable and flexible structure. Its ability to be applied to different surfaces through transfer methods provides access to areas that traditional UV printing cannot reach.

This technology offers major advantages especially for curved, recessed, or machine-incompatible products. It has become an ideal solution for promotional items, small-scale personalized designs, and boutique projects.

UV DTF is not an alternative to traditional UV printing; when evaluated as a complementary solution, it provides businesses with a broader service portfolio.

Business and Investment-Oriented Approaches

Investing in UV printing technology does not simply mean purchasing a machine. Proper planning, cost analysis, and long-term strategy are among the key factors that determine the success of this investment.

Calculating Hidden Costs in UV Printing Machine Investments

A machine investment that appears attractive at first glance can become more expensive than expected if hidden costs are not taken into account. Ink consumption, maintenance expenses, spare parts, and technical service costs must all be carefully evaluated.

In addition, energy consumption and waste rates during production have a significant impact on total costs. Energy-efficient solutions such as LED curing systems help reduce these costs in the long run.

When making an investment decision, it is essential to consider not only today, but also a perspective of at least 3–5 years.

A Success Guide for Beginners in the UV Printing Business

The biggest mistake for those new to the UV printing business is trying to do every type of job. Instead, choosing a specific niche both accelerates the learning process and strengthens brand perception.

Defining the right customer profile, setting clear pricing, and establishing quality standards from the beginning are crucial. In addition, after-sales support and communication directly affect customer loyalty.

During this process, analyzing the sectoral perspective of experienced players such as PASS Dijital can be highly instructive for new entrants.

UV Printing and Smart Manufacturing Integration in the Industry 4.0 Era

Industry 4.0 is also transforming the UV printing sector. Automation, data analytics, and remote monitoring systems make production processes more efficient. Smart manufacturing integration reduces error rates while increasing capacity utilization.

The software integration of UV printing machines ensures traceability throughout the entire process, from order to production. This provides significant advantages in both quality control and customer satisfaction.

For businesses that want to remain competitive in the future, digitalization is no longer an option but a necessity.